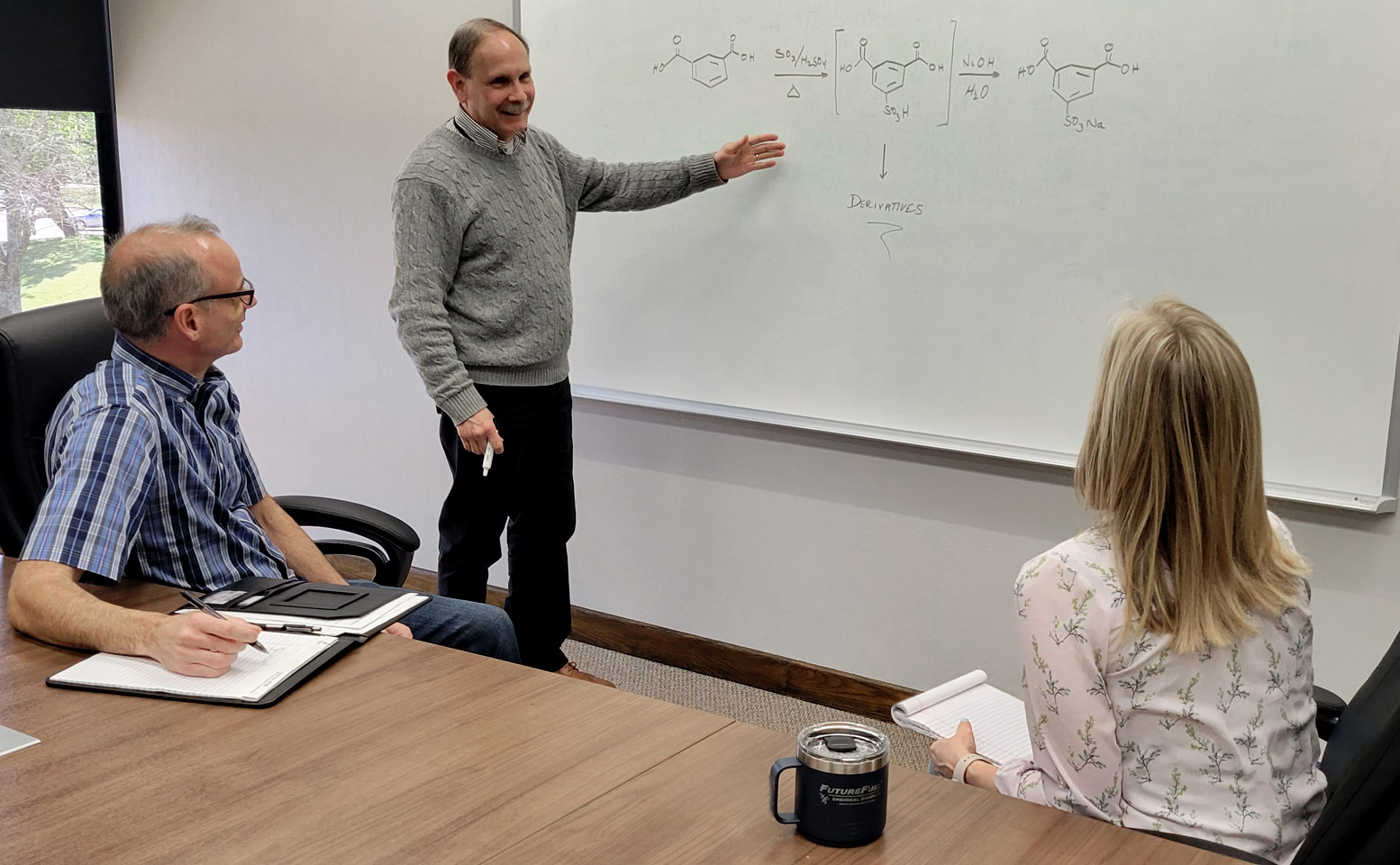

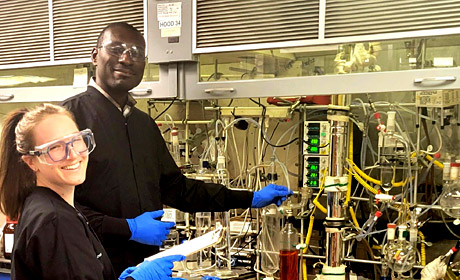

The Customization Process: Turning Ideas into Reality

Our customization process begins with a customer’s target compound. Our development laboratories, staffed with highly trained chemists, tackle the challenge of creating a synthesis procedure. The Process Hazard Evaluation and Scaleup (PHES) Laboratory evaluates the process and ensures the safety of full-scale operations. Process Engineering scales it to the manufacturing plant while Project Engineering and construction groups turn the design into reality, delivering the final product efficiently. Already have a well developed technical package for your product? FutureFuel’s experienced teams facilitate a seamless technology transfer, ensuring a cohesive and efficient integration of your specifications into our processes.